Summary

Contact angle refers to the tangent line at the intersection of gas, liquid, and solid phases at the gas-liquid interface. This tangent line forms the angle θ between the liquid side and the solid-liquid boundary line. Contact angle measurement is currently the main method for surface performance testing.

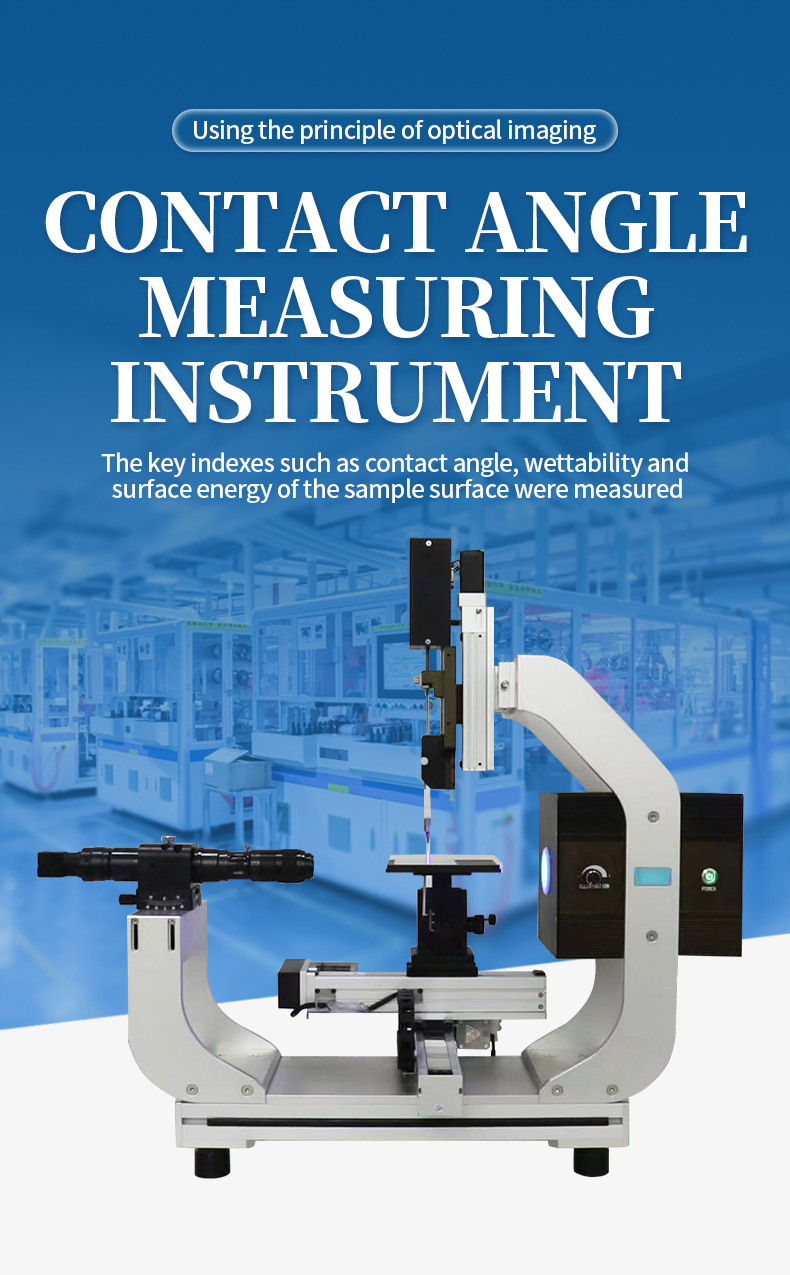

The SDC-350 integral tilt contact angle measuring instrument adopts the principle of optical imaging to measure the surface contact angle, wetting performance, interfacial tension, surface energy, rolling (sliding angle), forward and backward angle, and hysteresis of the sample through image contour analysis. The equipment adopts a fully automatic liquid inlet device and an automatic integral tilt device, which has comprehensive functions, high cost-effectiveness, and can meet various conventional measurement needs. It is currently widely used in many universities, colleges, and enterprises.

Application

Contact angle measuring instruments are widely used in various industries, such as mobile phone manufacturing, glass manufacturing, surface treatment, material research, chemical engineering, semiconductor manufacturing, coatings and inks, electronic circuits, textile fibers, medical biology, etc. Contact angle measurement has become an important instrument for evaluating surface performance.

(Some testing functions require the purchase of specialized accessories to complete)

1. The wetting behavior of liquids on solid surfaces, such as spreading, permeation, and absorption, is measured by the droplet method to determine the static contact angle;

2. Measurement of the advance angle, retreat angle, contact angle hysteresis, rolling angle, and dynamic contact angle of materials on solid surfaces;

3. Continuous real-time research and process recording of absorbing materials, analysis of contact angle variation curve over time;

4. Contact angle measurement of various special materials, such as powders, curved surfaces, superhydrophobic/superhydrophilic samples;

5. Contact angle test of materials immersed in liquid using the attachment drop method;

6. The suspended droplet method is used to measure the interfacial tension, polarity, and dispersion components of various liquids;

7. Calculate the surface free energy of solids and analyze its polar dispersion components;

8. Analyze the adhesion energy of liquids on solid surfaces, evaluate the uniformity and cleanliness of solid surfaces, etc.

Principle

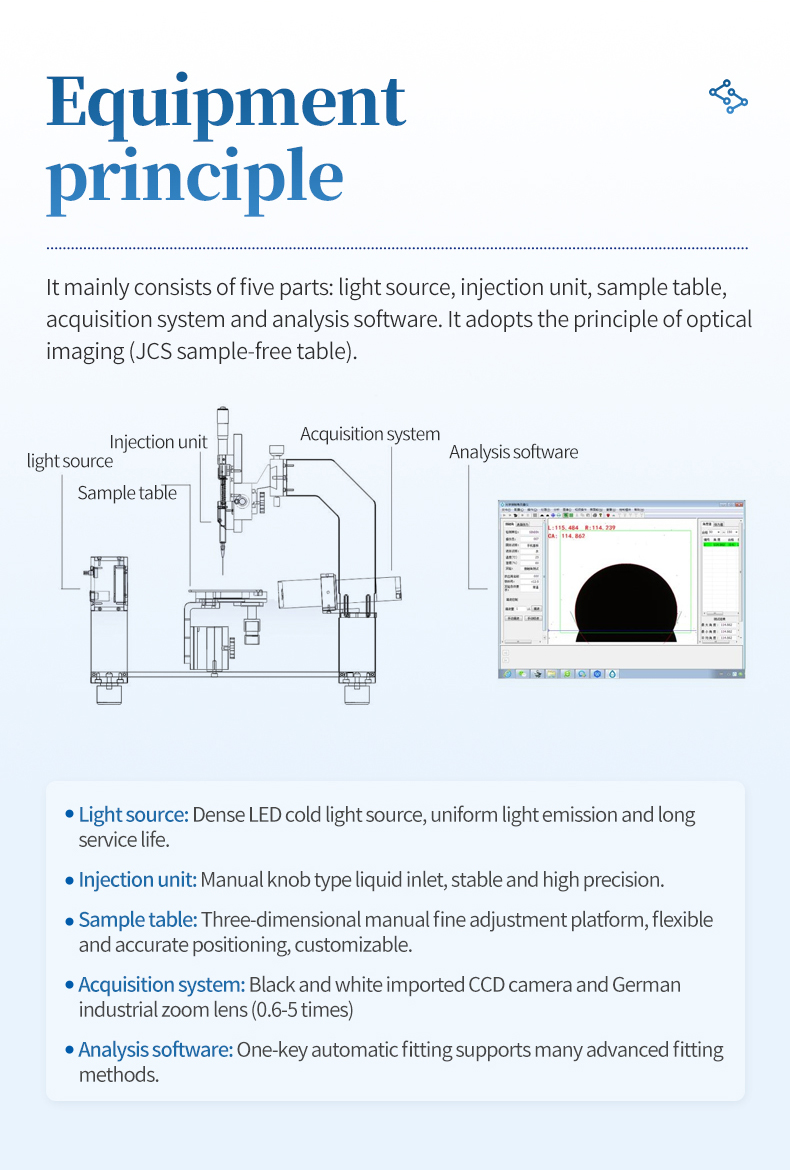

The contact angle measuring instrument mainly consists of six parts: light source, injection unit, sample stage, acquisition system, overall tilt platform, and analysis software. The equipment adopts the principle of optical imaging.

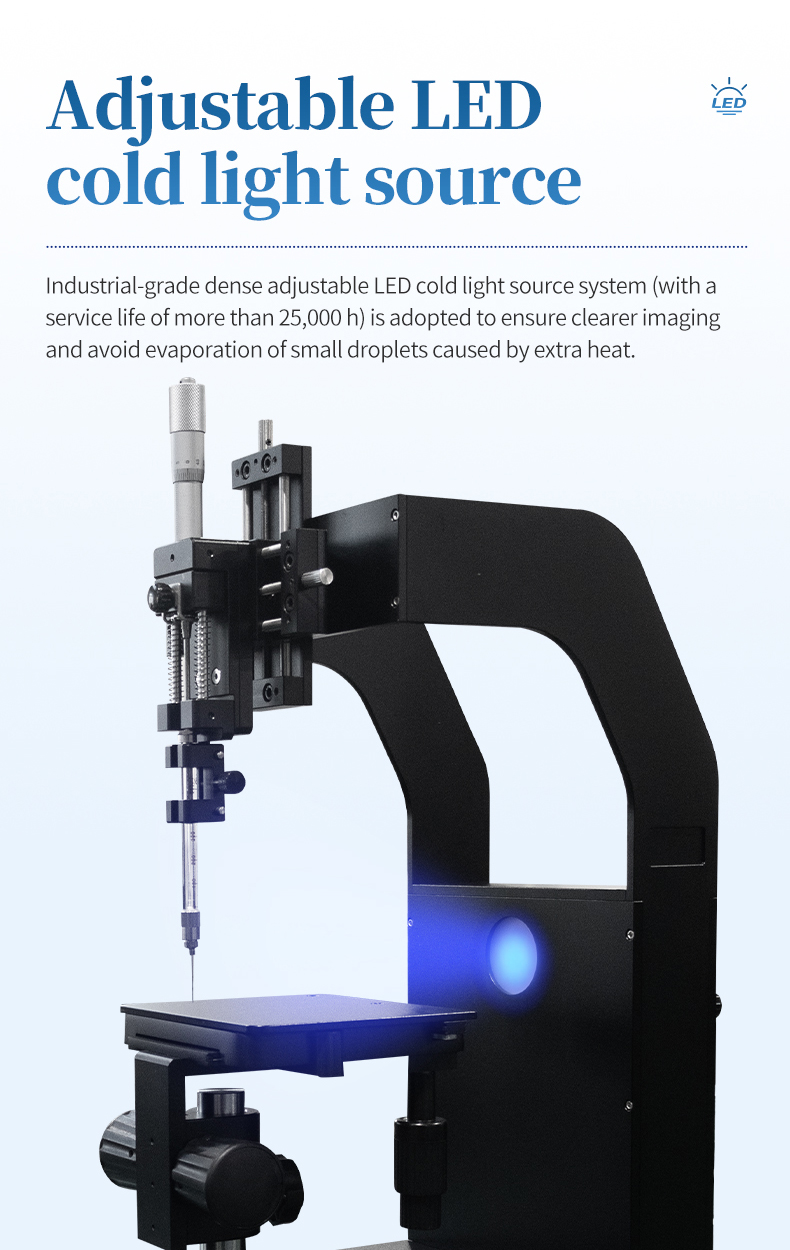

The light source adopts a dense LED cold light design, with uniform light emission, image cleaning, and long lifespan;

The injection unit adopts a high-precision injection pump for liquid injection, which is controlled by software for quantitative and speed control, ensuring stable dripping and extremely high accuracy;

The sample stage adopts a three-dimensional manual precision adjustment platform, which is flexible in operation and accurate in positioning. The sample stage can be customized according to the actual sample size;

The acquisition system adopts a black and white imported CCD camera, with stable shooting, clear images, and reliable authenticity. The lens adopts German industrial grade imported configuration, with adjustable magnification of 0.7-4.5 times, and no distortion or distortion in imaging;

The overall tilt platform adopts high-precision software control for tilt, with an accuracy of up to 0.01 °

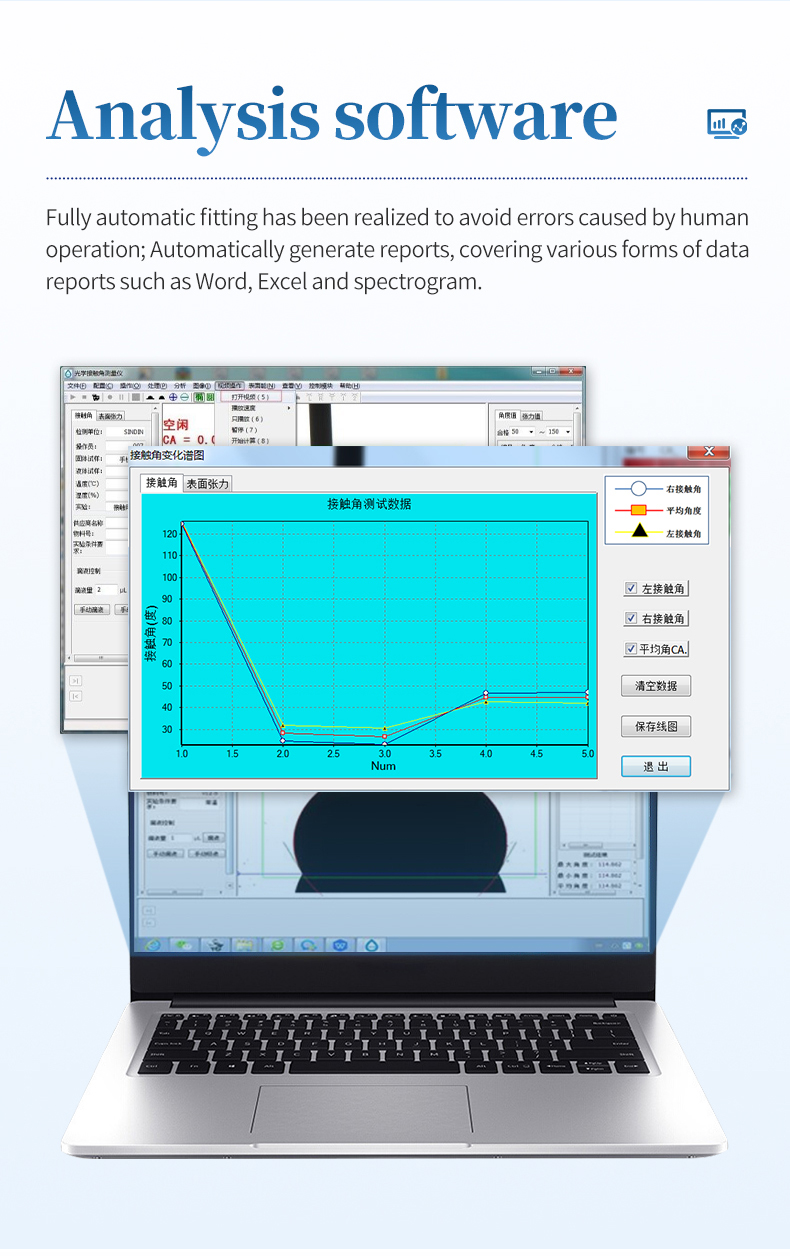

The analysis software has powerful functions, with one click fully automatic fitting ability and the most advanced fitting method internationally, meeting the precise fitting of various droplet shapes;

Specifications

Contact angle host | |

Dimensions | 750mm (length) * 408mm (width) * 695mm (height) |

Weight | 30.5KG |

Power supply | 220V/60HZ |

Light source system | |

Light source | Dense LED adjustable blue tone industrial grade cold light source |

Lifespan | With a service life of over 25000 hours |

Injection unit | |

Syringe | Specialized high-precision quartz syringe with a capacity of 500 μ L |

Dropping | Software controlled automatic liquid feeding, with an accuracy of up to 0.01 μ L |

Injection unit movement | up and down 50mm; left and right 50mm |

Data acquisition system | |

CCD | SONY imported high-speed industrial grade chip, 25 frames per second, 130W pixels |

Lens | 0.7-4.5 times high-definition industrial grade continuous zoom microscope |

Collection system adjustment | Front and rear 100mm (3mm fine adjustment), adjustable viewing angle (multiple viewing angles such as head up, top view, 360 ° rotation, etc.) |

Sample stage device | |

Workbench size | 120mm * 150mm |

Maximum sample size | 6 inches |

Sample stage movement | manual forward and backward movement, with a stroke of 60mm and an accuracy of about 0.1mm. Manual movement |

up and down movement, with a stroke of 35mm and an accuracy of 0.1mm. Manual movement | up and down movement, with a stroke of 80mm and an accuracy of 0.1mm |

Overall tilt platform | tilt range ± 90 °, tilt accuracy ± 0.01 °, adjustable tilt rate |

Analysis software | |

Contact angle measurement range | 0-180 ° |

Contact angle measurement accuracy | ± 0.1 ° |

Surface tension measurement range | 0-2000mN/m |

Measurement accuracy of surface tension | 0.01 mN/m |

Analysis software functions | 1. The most advanced contact angle measurement and analysis software in China uses automatic fitting method (one click automatic fitting, without manual error), including Circle method fitting, Ellipse/Oblique ellipse fitting, LY, Differential circle method; 2. Dynamic contact angle fitting (batch fitting of multiple images) includes wettability testing, video continuous fitting calculation (Video analysis); 3. Surface energy calculation; 4. Forward and backward angle measurement; 5. Rolling angle measurement 6, surface tension measurement; 7. Adhesion work; |

Accord with national standard

1. GB/T 24368-2009 (Detection of Hydrophobic Contaminants on Glass Surfaces);

2. SY/T5153-2007 (Determination Method for Wettability of Reservoir Rocks);

3. ASTM D 724-99 (2003) (Test Method for Surface Wettability of Paper);

4. ASTM D5946-2004 (Measurement of Contact Angle between Plastic Film and Water);

5. ISO15989 (Measurement of water contact angle of plastic film and thin plate corona treated film);

Product features

1. The mainframe adopts high-strength aviation aluminum alloy structure with modular design concept, independently developed integrated chip circuit control, and adopts the design essence and configuration of international top imported contact angle equipment to ensure that the instrument has extremely strong stability;

2. Adopting an industrial grade dense adjustable LED cold light source system (with a lifespan of over 25000H) to ensure clearer imaging and avoid the evaporation of small droplets caused by additional heat;

3. Adopting high-performance Japanese imported industrial movement and industrial grade telecentric zoom lens, it can basically achieve image distortion free conditions, ensuring the best imaging effect;

4. Adopting USB 2.0 standard interface, it has fast data transmission speed, high compatibility, and strong imaging stability;

5. The first domestic provider of contact angle measurement calibration samples imported from Germany, ensuring the accuracy of the instrument, with angle calibration standard plates at 3 ° 5 ° 8 °; 60 °90 ° 120 ° ; 115 ° (optional);

6. The collection system design is flexible and suitable for the vast majority of measurement environments, and can easily handle various complex sample surface measurements;

7. We have the world's most advanced contact angle analysis method, which can accurately fit all types of droplet imaging, including Hengmei's unique differential ellipse and differential circle special liquid imaging fitting methods;

8. Adopting internationally leading calculation methods, the software has achieved fully automatic fitting to avoid errors caused by human operation;

9. Equipped with fast fitting function for bilateral contact angle measurement, it can comprehensively analyze the surface wetting performance of liquids and solids, and more accurately analyze the actual wetting situation of the surface;

10. Dynamic shooting and rapid video testing data can continuously record changes in the test contact angle, which can then be automatically fitted in batches by software;

11. The software automatically generates reports, including various data reports in Word format, Excel format, spectrum format, etc;

12. With a variety of optional functional components, our strong R&D team can meet various customized measurement requirements proposed by customers;

13. Equipped with forward and backward angle measurement function, facilitating the most efficient measurement of sample surface stability performance;

14. Equipped with rolling angle measurement function, it can intelligently distinguish the sliding points on the material surface and measure the forward and backward angles in this way;

Address of this article:http://www.labinstruments.net/pro25/137.html

- Previous: Contact Angle Meter

- Next: Contact Angle Tester