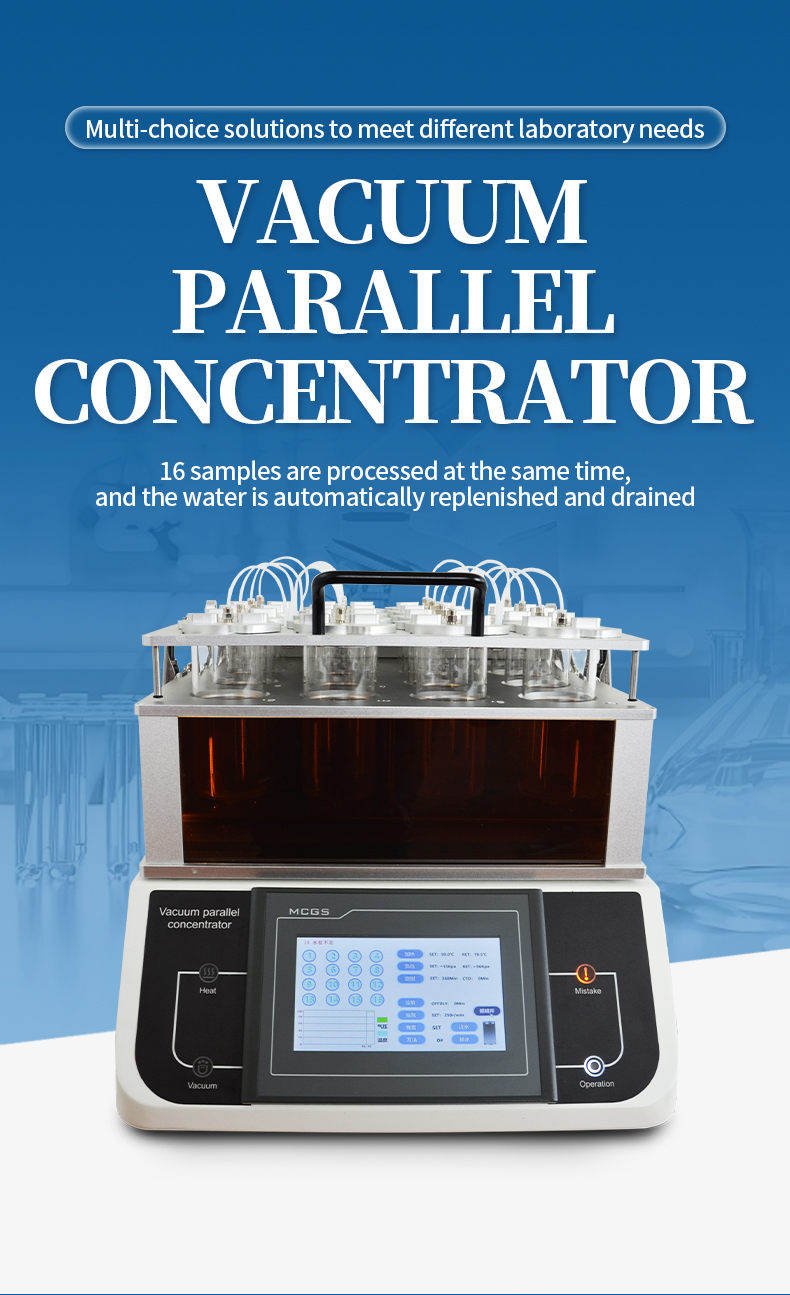

Product Application:

The vacuum parallel concentrator can perform separate or centralized closed evaporation/concentration on multiple samples, quickly and effectively recovering solvents, reducing the total evaporation time of multiple samples, increasing processing capacity, saving experimental time and resources. The installation and operation of the parallel evaporator are simple and flexible to use. Due to highly consistent processing conditions, parallelism is also better. Parallel evaporator is mainly used for evaporation and concentration of samples in chemical, pharmaceutical, biological, environmental protection, testing or other industries.

Application fields:

Pesticide residue analysis: vegetables, fruits, grains, plant tissues, etc

Environmental analysis: drinking water, groundwater, and pollutants, etc

Food and beverages: milk, alcohol, beer, etc

Bioanalysis: Serum, plasma, blood, urine, etc

Pharmaceutical drug testing: traditional Chinese medicine pharmaceuticals, etc

Product Features

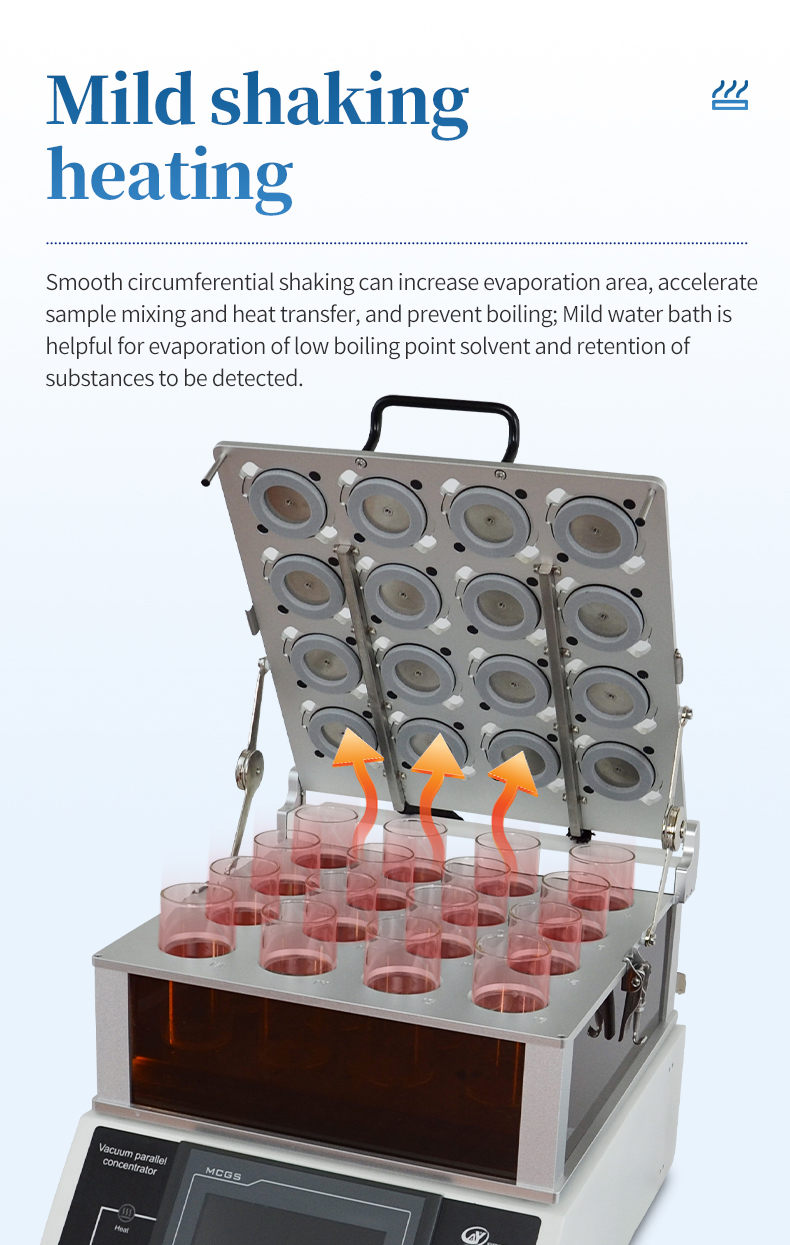

Three sided transparent glass design for easy observation.

The vacuum sealed lid has an independent access function and can accommodate any fixed volume bottle during operation.

Each vacuum pipeline is independently connected to avoid sample cross contamination.

The lower cover adopts an upward flipping design, which can be gently lifted to stop at will without the need to disassemble or move.

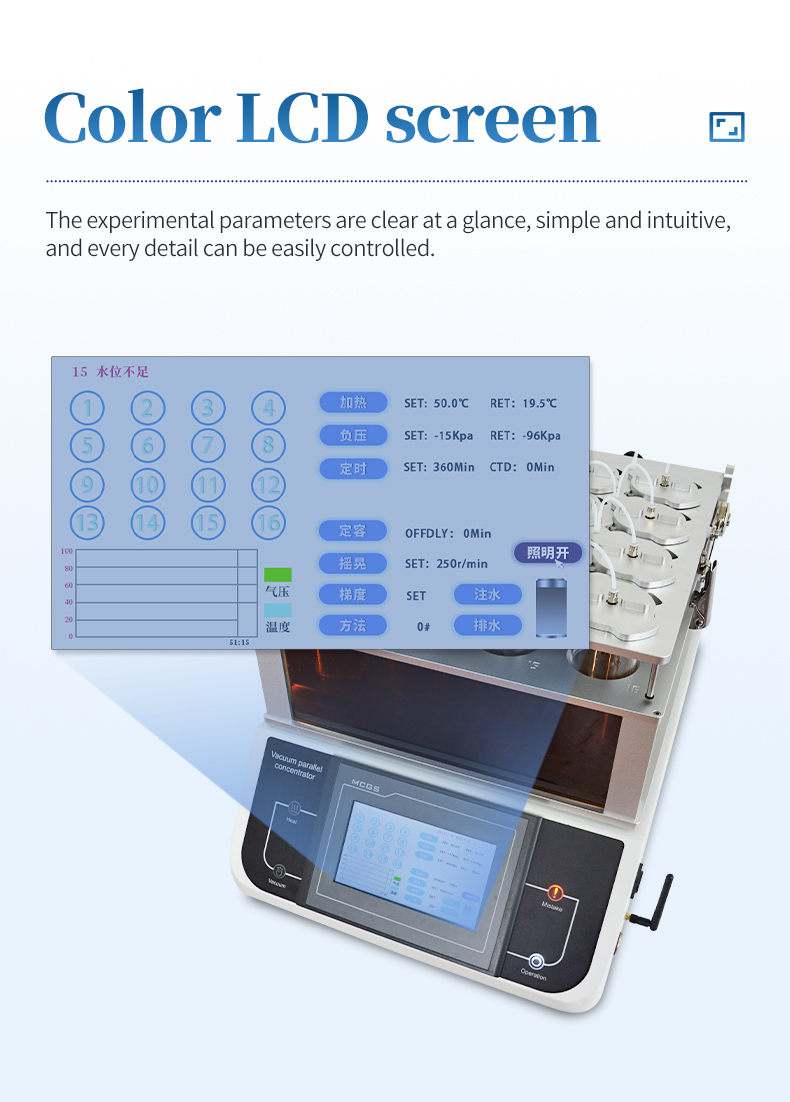

The operation of lighting, shaking, drainage, and pressure relief can be independently turned on and off to meet complex experimental needs.

The water temperature, shaking speed, and vacuum degree are adjustable, and the 16 channel vacuum is independently opened. The system supports gradient negative pressure.

Using water with a high specific heat capacity as the heat transfer medium, the temperature of each pore is consistent to maintain high parallelism of the sample during the concentration process.

The dedicated volumetric flask can concentrate 250ml of sample solution, and the concentration can reach 1ml.

Each channel is equipped with a constant volume sensor to avoid losses caused by excessive concentration of the sample solution.

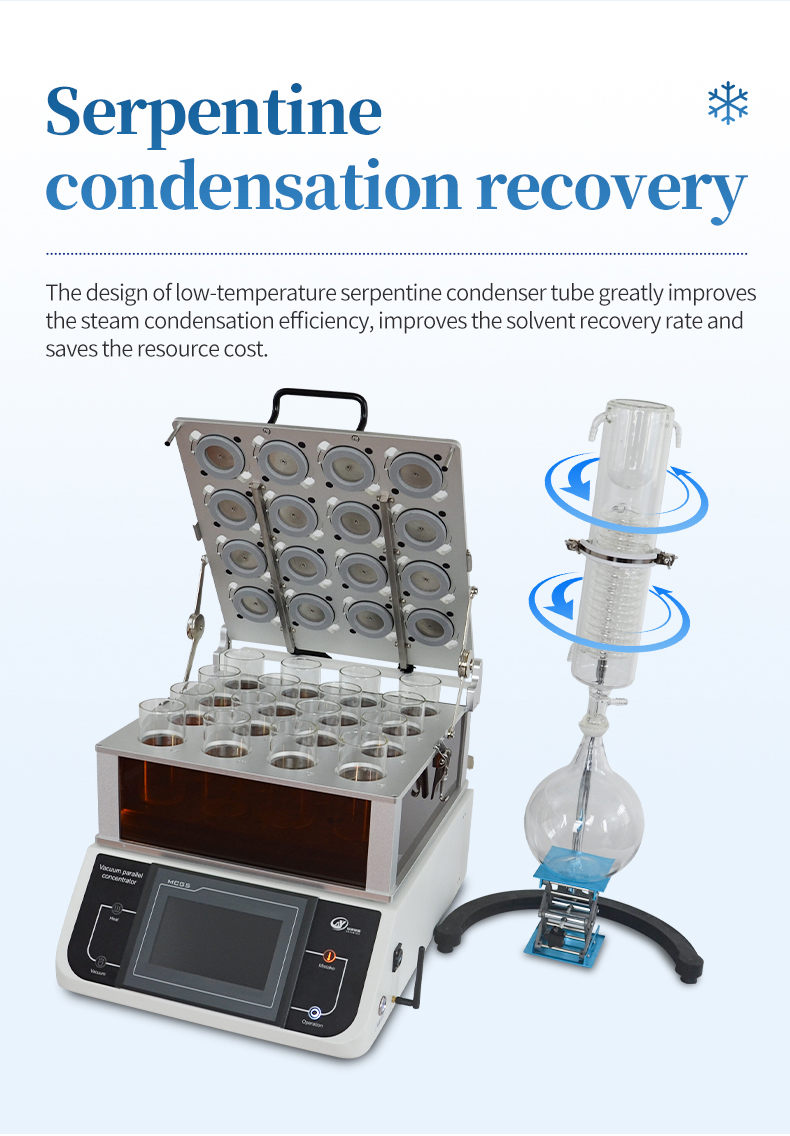

Using low-temperature serpentine condenser tubes for steam condensation, with a large condensation area and high recovery efficiency.

Smooth circular shaking, increase evaporation area, accelerate sample mixing and heat transfer, and avoid sample boiling. A mild water bath environment is conducive to the evaporation of low boiling point solvents and the retention of the target substance during the volatilization process. The digital vacuum control mode uses high-sensitivity sensors to detect the vacuum degree in real time, avoiding the loss of the target analyte caused by the sample liquid boiling under low pressure.

Easy to operate and safe: flexible working parameter settings, convenient sample insertion/extraction process, easy to learn and use; The fully enclosed design of the evaporation channel can avoid the harm of organic volatile components to the instrument and operators.

Address of this article:http://www.labinstruments.net/pro29/157.html

- Previous: Vacuum Parallel Concentrator

- Next: no more