1. Introduction

• Document Version: V1.1

• Compilation Unit: Shandong Hengmei Electronic Technology Co., Ltd.

• Compilation Date: 2025.12

• Core Positioning: A comprehensive, structured knowledge base covering all technical details, functions, and application scenarios of Hengmei's automatic potentiometric titrators (HM-D1, HM-D2, HM-D3, HM-D4).

2. Table of Contents

1. Introduction

2. Table of Contents

3. Product Basic Information

4. Core Technologies & Functional Features

5. Detailed Technical Parameters

6. Application Scenarios & Industry Adaptation

7. Accessories & Consumables Configuration

8. Model Comparison & Selection Recommendations

9. Instrument Installation Steps

10. Instrument Operation Procedures

11. Sample Testing Steps

3. Product Basic Information

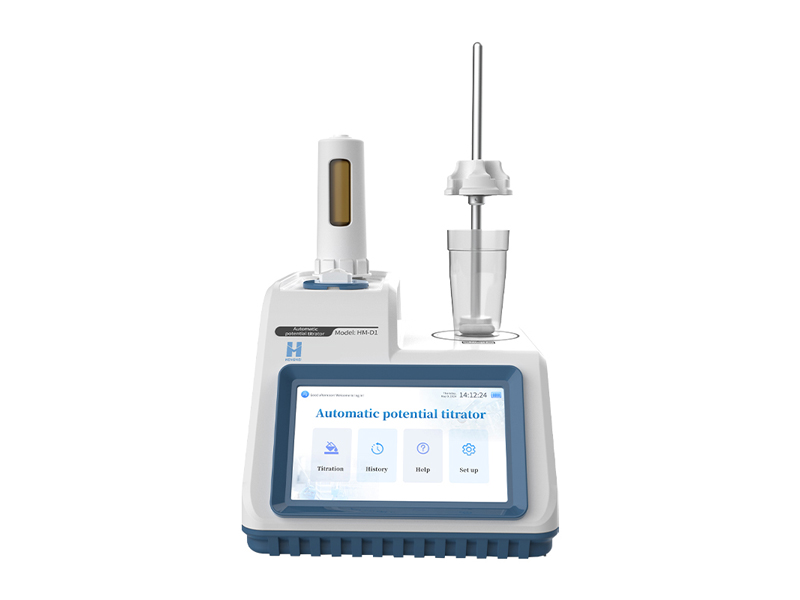

3.1 Product Overview

Hengmei automatic potentiometric titrators are precision chemical analysis instruments that determine the concentration of specific components in samples by automatically adding titrants. Based on the potentiometric titration principle, they identify endpoints through changes in cell electromotive force during titration. All models comply with national verification regulation JJG 814-2015, meeting Class 0.05 standards with a maximum indication error of ±1.5% and repeatability ≤0.2%.

3.2 Model Range

• HM-D1: Basic model supporting potentiometric titration and pH measurement

• HM-D2: Enhanced model with additional conductivity titration function

• HM-D3: Specialized model with dead-stop titration capability

• HM-D4: Comprehensive model integrating conductivity and dead-stop titration

3.3 Basic Configuration

All models feature Android 10 operating system, 7-inch touchscreen display, 100,000-record data storage, and multiple data interfaces (USB/WiFi/Ethernet). They operate on AC 110V-240V/50-60Hz power supply, with dimensions 310×226×233mm and weight 3.7kg. Built-in thermal printers and compliance with environmental requirements (operating temperature: 0-40℃, humidity: 10%-75%; storage temperature: 0-40℃, humidity: 10%-90%) are standard across the series.

4. Core Technologies & Functional Features

4.1 Titration Modes

Support potentiometric titration, pH measurement, and optional conductivity/dead-stop titration (model-dependent). Compatible with acid-base, redox, precipitation, and complexometric titrations via electrode selection.

4.2 Operational Flexibility

Offer dynamic, equidistant, and manual titration methods. Support preset endpoints or automatic endpoint recognition, customizable calculation formulas, and storage of up to 100 user-defined titration methods for quick access.

4.3 Precision Enhancement Functions

Three key error-reduction features: air purging (eliminates pipeline bubbles), pipe flushing (minimizes reagent waste and mixing errors), and pipe emptying (prevents chemical spills during disassembly).

4.4 Intelligent Operation

Magnetic stirring replaces manual shaking; precision metering pumps substitute traditional burettes. Automatic data calculation, storage, printing, and remote transmission streamline workflow.

5. Detailed Technical Parameters

5.1 Common Parameters (All Models)

• Titration repeatability: ≤0.2%; titration error: ≤1.5%

• Burette accuracy: ±5μL (10mL), ±10μL (20mL); error: 10μL/10mL (10mL), 20μL/10mL (20mL)

• Potential range: -2000 to 2000mV; resolution: 0.1mV; basic error: ±0.25‰/FS; stability: ±0.3mV/3h

• pH range: 0-14; resolution: 0.01pH; basic error: ±0.01pH

• Temperature measurement: -5 to 105℃; resolution: 0.1℃; error: 0.2℃

5.2 Model-Specific Parameters

• HM-D2: Conductivity range 0.00μS/cm-2000mS/cm; basic error ±1.0% FS; stability ±1.0% FS

• HM-D3: Dead-stop polarization voltage (30mV/50mV/100mV); current range 0.00uA-200uA; voltage error ±1mV; current error ±1.0% FS

• HM-D4: Combines HM-D2 and HM-D3 parameters (conductivity + dead-stop titration functions)

6. Application Scenarios & Industry Adaptation

Widely used as a laboratory basic instrument across industries including food testing, pharmaceutical inspection, disease control, commodity inspection, water treatment, petroleum, chemical engineering, marine research, power generation, environmental protection, new energy, education, and scientific research. Suitable for routine analysis, quality control, and academic research requiring high-precision titration.

7. Accessories & Consumables Configuration

7.1 Standard Accessories

Host (1 unit), power cable (1), 10mL/20mL burettes (1 each), support rod (1), five-hole electrode holder (1 set), burette sleeve (1), Teflon tube (1.5m), PVC hose protective cover (1.5m), PEEK quick-connect fittings (6 sets), titration pen (1), titration pen tips (5), 100mL titration beakers (5), 30mm/40mm stir bars (1 each), reagent bottles with caps (2 sets), visual filters (2 sets), CO2 absorbent (1 bottle), and documentation (manual, warranty card, certificate of conformity).

7.2 Standard Electrodes

• HM-D1: 6501 glass composite electrode (acid-base titration), 5004 redox electrode, 2616 composite silver electrode (precipitation/cloride ion), T-2 ATC temperature electrode

• HM-D2: Adds DJS-1C bright conductivity electrode

• HM-D3: Adds 260C bright dead-stop electrode

• HM-D4: Full set (all electrodes from HM-D1, D2, D3)

8. Model Comparison & Selection Recommendations

• HM-D1: Ideal for basic labs needing standard titration (acid-base, redox, precipitation) and pH measurement

• HM-D2: Suitable for applications requiring conductivity titration (e.g., electrolyte analysis)

• HM-D3: Recommended for redox reactions requiring dead-stop titration (e.g., pharmaceutical analysis)

• HM-D4: Comprehensive solution for multi-method labs (combines all titration functions for versatile use)

9. Instrument Installation Steps

1. Connect interfaces: Power, reference electrode, working electrode, temperature electrode, network, and USB.

2. Install burette: Attach burette to the peristaltic pump's T-slot and secure with the sleeve.

3. Configure three-way valve: Connect inlet, pump, and titration ports as directed.

4. Assemble pipelines: Connect reagent bottle to three-way valve (Tube 1), three-way valve to pump (Tube 2), and three-way valve to titration pen (Tube 3).

5. Mount support: Fix the support rod and adjust the electrode holder height.

6. Prepare titration beaker and stir bar: Select appropriate stir bar size based on vessel type.

7. Install thermal printer paper: Open the printer cover, load paper, and confirm proper alignment.

10. Instrument Operation Procedures

1. Power on: Connect power and 启动 the Android 10 system.

2. Reset: Perform zero calibration (required after power-on or component replacement).

3. Method setup: Create/edit/save titration methods (configure parameters: reaction equation, titrant concentration, sample volume, endpoint mode).

4. Pretreatment: Set pre-stirring time, pre-add volume, and pre-add stirring time if needed.

5. Pipeline preparation: Execute cleaning (with deionized water) and flushing (with titrant) to remove contaminants.

6. Start titration: Place the sample beaker on the stirrer, immerse electrodes, and initiate titration.

7. Post-titration: Save/print/upload results; perform pipe emptying and cleaning.

11. Sample Testing Steps

1. Sample preparation: Measure a precise volume of undiluted sample using a calibrated device and transfer to a titration beaker; add a stir bar.

2. Electrode preparation: Treat electrodes per instructions (e.g., soak pH electrode) and mount on the holder.

3. Instrument configuration: Select or create a matching titration method; input sample details (volume, concentration).

4. Calibration: Perform pH/conductivity calibration if required (follow manual procedures).

5. Titration execution: Start stirring, initiate titration, and allow the instrument to auto-detect the endpoint.

6. Result analysis: Review concentration, volume, and content data; verify against standards.

7. Post-test: Clean electrodes, empty pipelines, and store instruments in a dry environment.

Article address:http://www.labinstruments.net/news/140.html